Products - 3D Cell

Expansion System

Products - 3D Cell

Expansion System

A Novel Integrated 3D Perfusion Bioreactor/Incubator System From 3D Biotek!

Product Info |

|

White Paper

The 3D Cell Expansion System (3D-CES) is an integrated system designed for large

scale expansion of anchorage-dependent cells in a 3-dimensional (3D)

microenvironment. Culture and expansion of a large quantity of cells by the

traditional two dimensional (2D) method is difficult and known to have many

challenges. The 3D-CES is designed to lift this inherent limitation of 2D cell

culture and expansion methods. With the 3D-CES, cells are grown and expanded on

3D polystyrene (PS) scaffolds. The unique dynamic system circulates media

throughout the system using a peristaltic pump providing an efficient exchange

of nutrients and waste between media and the cells. With minimum hands-on time,

this innovative technology is more efficient and significantly reduces the

amount of time, space, and labor needed to achieve the desired number of cells

in a shorter amount of time compared to other methods.

|

Highlight of the major Features

- Integrated Bioreactor/Incubator System for large-scale cell expansion

- Optimized for Stem Cell (Adipose-Derived & Bone Marrow) expansion

- Cells are seeded and grown on 3D Biotek's polystyrene scaffolds

- No need to change media in the entire expansion process

- Reduced human interaction to minimize chances of contamination

- Each culture chamber is capable of expanding up to 250 million cells in 14-18

days

- Two culture chamber design allows max expansion up to 500 million per production

run

- Great potential for use in stem cell therapy and bio-banking

- Also suitable for use in exosomes/protein production for cosmetic industry

|

|

Culture Chamber and Media Container

- The Culture Chamber and Media Container are placed inside a custom-made incubator which provides tubing connection through its side wall to the pump

- Culture Chamber can hold up to 15 pieces of polystyrene (PS) scaffolds

- Cells are seeded and expanded in the PS scaffold which provides a 3D micro-environment

- The capacity of cells for each culture chamber is about 200 - 300 million

- The Media Container can hold up to 3.5 liter

- For 200 - 300 million of cells, about 2.5 liter of media is needed

- Flow of media is from the Media Container in upward direction to the Culture Chamber through the PS scaffolds

|

|

Polystyrene (PS) Scaffold

- Fabricated by 3D Biotek's micro-fabrication technology

- Its unique feature is 100% connectivity within its structure which allows effective exchange of

nutrients and waste between the media and the cells

- PS scaffold is plasma-treated to enhence cell attachment

- The fiber and pore size are approximately 150 and 200 microns, respectively.

- The dimensions of each scaffold are approximately 105(W)x 66.5(D) x 0.6(H) mm

|

|

2-chamber design It allows a max capacity of about 500 million of cells per single run

|

|

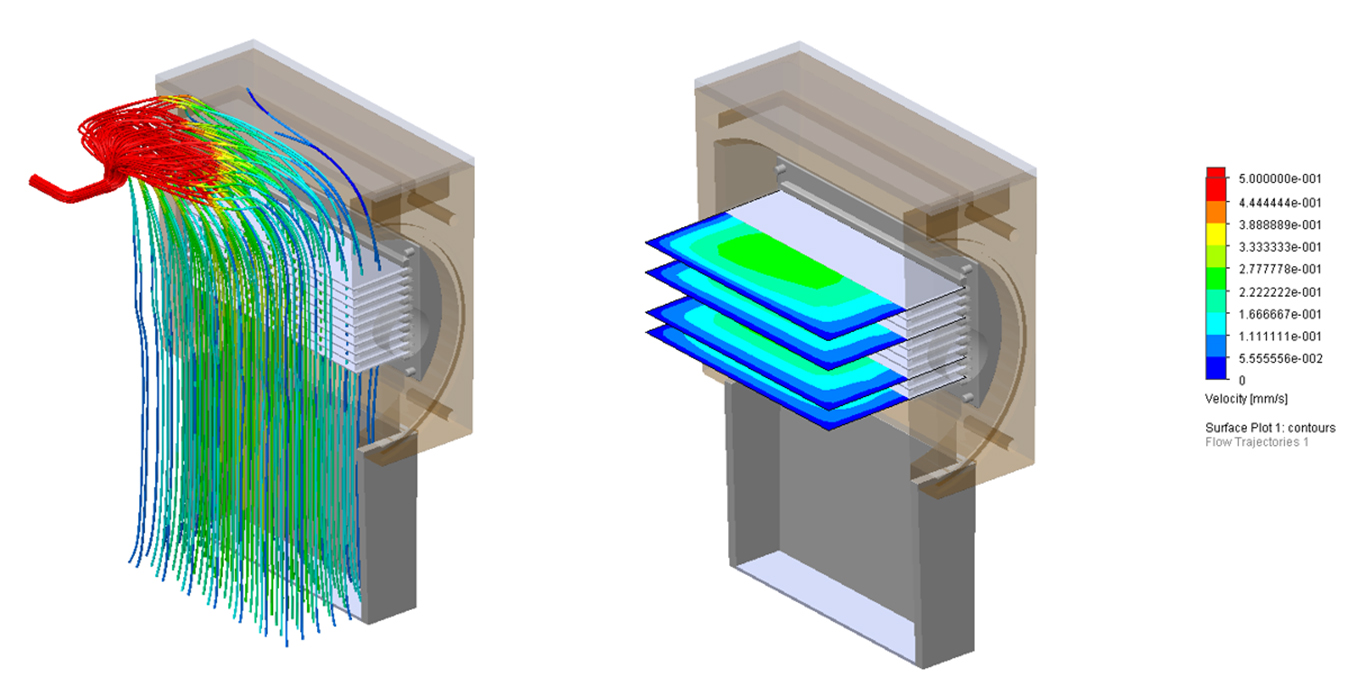

Comptational Fluid Dynamics (CFD) analysis

- CFD is used as a design tool for flow optimization

- It provide important parameters such as flow rate and max shear stress

- Max shear stress is below critical value

- Media flow is fairly uniform through the culture chamber and the scaffolds

|

|

|

|

| 3D Cell Expansion System is registered with US FDA as Class I medical device

|

|

|

|

For more product/pricing information, please call or email us at

info@3dbiotek.com